Carbon-fiber is a strong but lightweight material which plays a role in the production of various products, especially cars and planes. But drilling out of carbon fiber can be challenging. The surface can easily chip, causing problems during manufacturing. That’s where seat cushion drill bits come in. These unique instruments aid in the process to ensure you get a clean hole that won’t wreck the carbon fiber. Here at ZhongQi, we produce these drill bits with the latest techniques to make sure our customers have a great time working with carbon fiber.

How Does Seat Cushion Drill Bits Reduce Hole Chipping In Drilling Carbon Fiber?

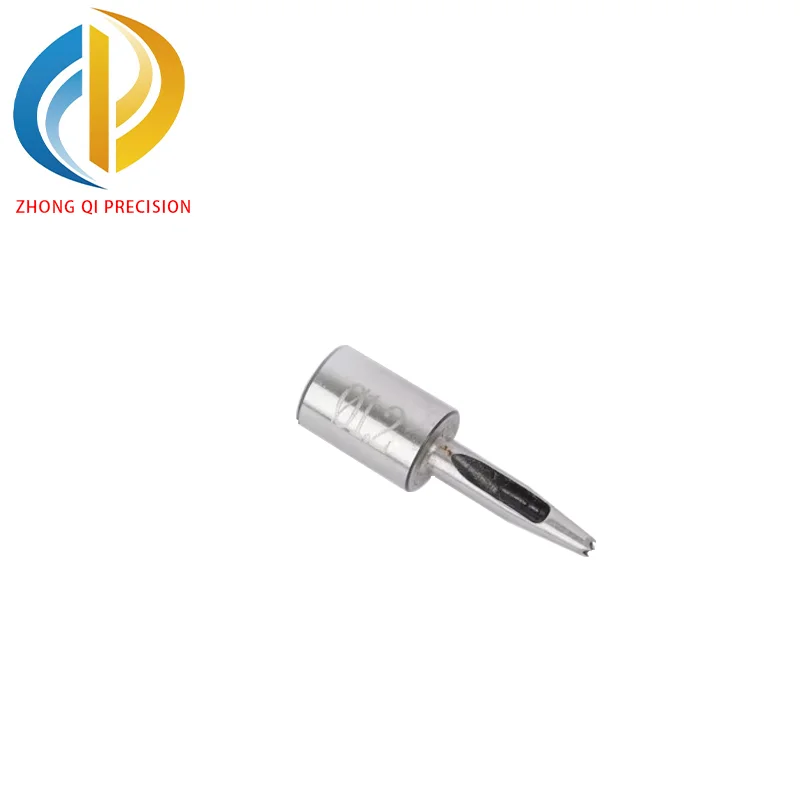

These seat cushioning style KB type drill bits come with special features to prevent chipping while drilling in carbon fiber. First, they are equipped with a cutting edge designed to slice through the material cleanly. This makes it so the drill cuts instead of rips fibers, which is generally what leads to chips. The grade of the cutting edge is also significant. Sharper is better, in other words cuts better, with less likelihood of damage. At Zhongqi, we take these angles very seriously in the process of production.

Also crucial is the type of material the drill bit is made from. Shorter, stronger metals like high-speed steel or carbide are commonly used because they hold an edge longer and do better against heat. This makes them able to bore through carbon fiber without frequent replacement. When that drill bit gets hot, it can melt a small amount of carbon fiber and leave the vibration-damping fabric to end in chipping. Our drill bits are engineered to keep cool, allowing you to make the most out of your drills.

There’s also the matter of what size bit to use. If the bit is too large, it will add unnecessary stress to the carbon fiber and chip or otherwise damage it. Our Zhongqi team presents you with a variety of sizes to meet your various requirements, so that each user can choose the appropriate size according to the actual situation of each project.

Lastly, correct drilling methods also contribute to reduce chipping. Exercise a firm and consistent pressure when drilling. Too much force can cause chipping. At Zhongqi we recommend training for individuals on how to effectively use our drill bits. This allows them to produce the best finish when dealing with carbon fiber.

The Best Seat Cushion Drill Bits for Carbon Fiber Drilling Sources For The Best Wholesale?

The best seat cushion wholesale drill bits may be difficult to find, however Zhongqi has made it easier. We have the drill bits designed for working specifically with carbon fiber. Our products are sold in-store, online through various retailers. When you need the best quality and reliability for your drill bits.

One place to look for the right bits is at our website. We offer a full description of each item, including material, size and features. This allows consumers to make informed decisions. We also have bulk pricing available. Purchasing wholesale could save businesses money, especially if they are in need of many drill bits for their projects.

Another strong possibility is to join us at industry trade shows or expos. These gatherings enable customers to meet with producers such as Zhongqi. Guests can see the drill extension up close and even discuss their exact needs with our team. This human touch can reassure customers about their purchase.

There are also the local distributors and suppliers where you can get our drill bits from. They frequently carry different sizes and kinds, so that customers can see what they are buying before they choose. It might also be useful to inquire for recommendations from other manufacturers who use carbon fiber. Those experiences can help guide you to the best products.

In conclusion, Zhongqi is your reliable manufacturer of superior seat cushion drill bit. Whether you are in the market for online or in person, such as at a trade show or shop through some of our local suppliers, our drill bits were created with carbon fiber workers in mind. This will give you peace of mind that your drilling projects will go off without a hitch or missing chunks.

Why Seat Cushion Taper Bits are a Must For Any High-Quality Carbon Fiber Work

The type of tools that you will need for this task will always depend on the job you are working on but if you’re dealing with carbon fiber, and more specifically it means doing something related to cars or airplanes then getting the right tool is very important. The seat cushion drill bit is one of the most important instruments that is used to drill into carbon fiber. These are uniquely shaped drill bits that cut through metal or porcelain but won’t hurt the material. Strong and lightweight, carbon fiber also can easily chip or crack if not handled carefully. Enter seat cushion drill bits. They have little details that allow them to smoothly cut through carbon fiber so they are suitable for any high quality project.

Seat cushion drill bits are built with special shapes and material compositions that let them plow through carbon fiber without harming it. These bits differ from regular drill bits, featuring a sharper cutting edge and more distinct tip shape to assist cutting tough materials. In other words, when you employ a seat cushion drill bit, there is far less chance of any chipping or cracking taking place around the hole that you are making. This feature is very useful for projects where the visual aspect and strength of the carbon fiber are important. For example, if you’re manufacturing a car seat or the part of an airplane, for instance, you want the holes to look good and be strong enough to withstand pressure. Zhongqi seat cushion drill bits can give you a way to exceed that standard, ensuring the quality of your work is always great.

The very fact that seat cushion drill bit is necessary because it can help you save time as well. When drilling with standard bits, you may need to spend additional time fixing the chips or breaks that occur. This might slow your project down and add to the cost. But with Zhongqi seat cushion drill bits, you can zoom through and get the job done right. This effectiveness definitely makes this a product worth having for anyone dealing with carbon fiber.

Solutions and Tips

To have an optimal result when working with seat cushion drill bits, you can adhere to some advices and solutions. First, ensure that the drill bit you are using is of the appropriate size for the hole you are drilling. There can be problems with a too-small or a too-large bit. Zhongqi comes in several sizes, so you can find the one that best matches your project. To be safe, as always, look through and analyze the specs of a seat cushion drill bit to make sure it will work best for you.

Another key is to get the right drill speed. If you drill too quickly, you could generate too much heat and damage the carbon fiber. When drilling, you will want to use a lower speed and apply constant pressure. It allows the seat cushion drill bit to easily cut through material without damaging the base. You could also use a little cutting oil to help cool the bit and make drilling easier.

Finally, when drilling wear protective gear. That includes safety glasses and gloves to shield your skin from any small particles that might fly off during the process. Safety is key, especially when dealing with such a tough material as carbon fibre. Following these helpful hints will make certain that you get the highest quality holes at all times in your carbon fiber projects, while at the same time eliminating any potential chipping or other damage.

When Used in Carbon Fiber Production, Where Can Seat Cushion Drill Bits be Most Effective?

Seat cushion drill bits in an adjustable position are best used for multiple locations on carbon fiber production. The automotive industry is one of the most usual places for LGN cutting. A lot of high-end cars have carbon fiber parts; it’s strong and lightweight. When fabricating these parts, accurate holes are critical for screws and other fasteners. Some Rhength seat drill bits offers an efficient way for manufacturers to generate perforations, which is also important for the safety and performance of the vehicle.

Another significant application of seat cushion drill bits is in aerospace production. Airplanes frequently include carbon fiber components to fly faster and more efficiently. For this field, accuracy is key. Seat cushion drill bits will help engineers and manufacturers make these required holes without taking the risk of damaging their materials. This is critical as it allows for the parts to fit perfectly and passengers and a crew can remain safe on-board.

Furthermore, seat cushion tool bits are also advantageous in the manufacture of sporting goods. Carbon fiber is used to make many high-end bicycles, tennis rackets and other gear strong and lightweight. It is what athletes use to play their very best. With Zhongqi seat cushion drill bit manufacturers feel safe that their product is of the highest level which can be trusted by the athlete in competition.

Seat cushion carbide drill seat cutter bits are one of the most useful tools in multiple industries. They protect from chipping and cracking to make the end products as attractive as they are useful. From automobile, aeroplane to sports gear manufacturing, the drill bit you use make all the difference in quality.

Table of Contents

- How Does Seat Cushion Drill Bits Reduce Hole Chipping In Drilling Carbon Fiber?

- The Best Seat Cushion Drill Bits for Carbon Fiber Drilling Sources For The Best Wholesale?

- Why Seat Cushion Taper Bits are a Must For Any High-Quality Carbon Fiber Work

- Solutions and Tips

- When Used in Carbon Fiber Production, Where Can Seat Cushion Drill Bits be Most Effective?