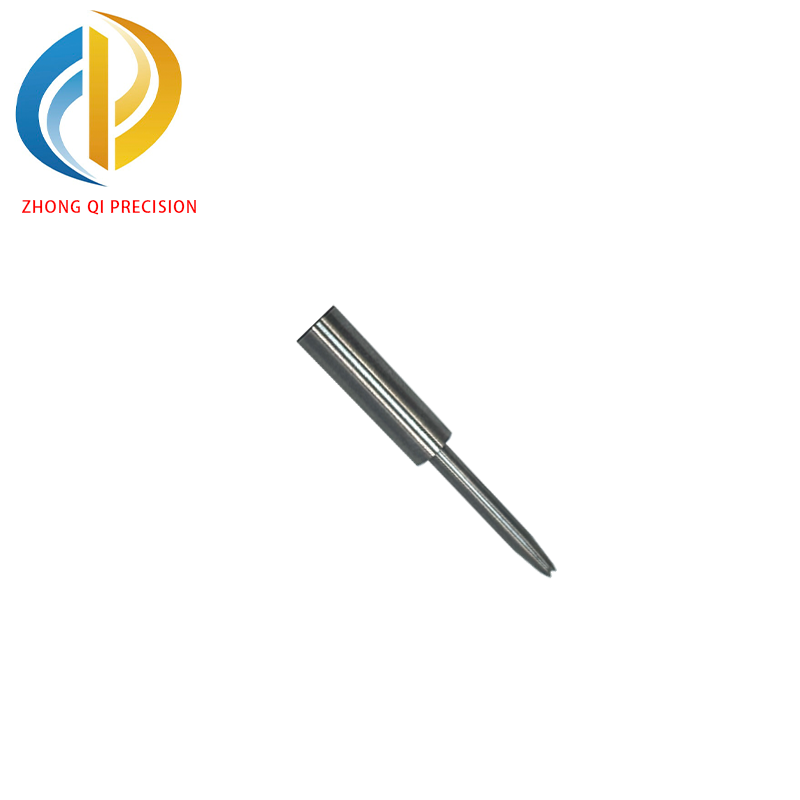

Along with elements such as marking pins, manufacturing facilities often depend on devices towards form as well as slick products. Punching devices as well as laser device reducing devices are actually two common kinds. These devices are actually utilized through Zhongqi in its own manufacturing procedure. A punching device utilizes a strike towards produce openings or even reduce one thing away from sheets of steel. They fast, as well as a lot of all of them could be created at the same time. A laser device reducing device, however, reduces products through a concentrated beam. This method could be utilized for extremely precise reduces as well as a selection of products

Punching vs. Laser Cutting Machines: A Comparison What are the main differences between punching and laser cutting machines

Punching machine and laser cutting machine are different working methods. Punching machines have a punch that pushes into the metal sheet. This makes holes or cuts shapes out. It’s typically faster than laser cutting for simple designs. For instance, if you need a lot of round holes punched into metal sheeting, the way to go is punching machine. But punch machines can have difficulty processing very detailed designs. If the shape is complex, or contains smaller features, the punch may be unable to form it correctly

Laser-cutting devices, of the range utilized through Zhongqi, work in a different way. They utilize a beam of light of laser device illumination, which is actually extreme as well as can easily puncture certainly not just steel however likewise lots of various other products. Simply put, you can easily reduce timber in addition to plastic as well as others. The laser device is actually operate through a computer system, therefore each style could be as great as well as outlined as you desire. For example, if you preferred towards reduce the form of a celebrity which contains extremely little sharp collections, this is actually rather quickly attainable through a laser device reducing device

What Do Wholesale Buyers Need to Know About Laser Cutting Technology

Certainly there certainly are actually some essential aspects around laser device reducing innovation that wholesale purchasers ought to understand. Laser device reducing has actually the significant benefit of being actually precise. Since when you select this path, the sides are actually cleanse, reduces crisp. That is particularly essential if both components should suit along with severe accuracy, as they perform in equipment as well as electronic devices. For instance, if you are actually creating components to become signed up with with each other, any type of small mistake in reducing can easily trigger problems. There is a lot much less of a possibility along with laser device reducing

Likewise think about exactly how versatile the product could be. Laser device reducing can easily fit a selection of products. Steel, plastic or even timber, laser device reducing can easily fit your requirements. This works for dealers that wish to try out option products in their items. Zhongqi might have the ability to help you using this versatility as our team maintain our customer demands

Punching Machine vs. Laser for Your Business, What to Choose

When it comes to selecting a machine for your business, there are two types that are very popular: punching machines and laser cutters. Both can be helpful in making products, but they operate differently. A punching machine is a press that’s used to cut holes and create contours in materials like sheet metal and plastic. Its grip is tight, and it takes form by punching out material. In comparison, a laser cutter cuts through materials using a strong beam of light. This light is highly concentrated and can create extremely thin cuts

Towards determine which device is actually finest for you, think about exactly just what you desire. A punching device may be the method towards go if you are actually creating great deals of the exact very same form. It is great for automation, which is actually towards state you can easily create a great deal of whatever it remains in a brief duration. However if you wish to reduce much a lot extra elaborate styles, or even require stronger forms, after that you may be much a lot better off along with a device such as a laser device cutter. Laser device cutters can easily reconfigure exactly just what they reduce without the require for brand-brand new devices

Common use problems of punching and laser cutting parallel machine What are the common use problems of punch-laser parallel machine

Like all machines, punching machines and laser cutters are plagued by problems. Understanding such problems might have allowed you to avoid them. A common challenge with punching machines is that they require the correct die to form a specific shape. If that is a worn out or damaged die, you’ll end up with bad cuts, and then it’s all over. In addition, punching machines, as they are called, can produce sharp edging on their pieces. Workers need to be careful of these edges to avoid injury

Laser cutters are not without their difficulties. Most of the problems associated with them is the amount you have to take off and on each time depending on how thick your material is cut. If you’re cutting something very thick, this can be time-consuming. Additionally, laser cutters need maintenance. The lens can become dirty, which diminishes the quality of the cut. Keeping clean the machine is very essential to keep it running smoothly

A second element to weigh is safety. Punching can be noisy and even dangerous if one does not know how to punch properly. In order to be safe, workers have to wear protective clothing. Laser cutters, though potentially safer in some respects, can also inflict burns or eye damage if proper safety precautions are not observed. At Zhongqi, we often suggest you to train your workers on how to operate these machines safely so that an accident won't happen

What Are The Benefits Of Using Laser Cutting As Opposed To Flashing

Certainly there certainly are actually lots of benefits towards laser device reducing versus traditional punching devices. Among the most significant benefits is actually precision. A laser device cutter can possibly do extremely great, precise reducing along with fat chance of mistake. This is actually likewise enables towards produce much a lot extra complicated designs that will or else be actually challenging to create along with a punching device. If your company is actually marking out fancy designs or even complicated forms, effectively, a laser device cutter can possibly do that along with the rate as well as integrity you require

Another profit is actually really flexibility. Together with a laser device gadget cutter, you can easily quickly simply change out precisely simply exactly just what you decrease without altering out your gadget. If you acquire affected in the direction of try a new design, you can potentially perform for that reason pronto! This suggests you can easily quickly stay before designs in addition to produce precisely simply exactly just what customers are actually really asking for. However, it is actually really often prolonged in addition to expensive to change a design on a punching gadget which requirements changing the pass away

Table of Contents

- Punching vs. Laser Cutting Machines: A Comparison What are the main differences between punching and laser cutting machines

- What Do Wholesale Buyers Need to Know About Laser Cutting Technology

- Punching Machine vs. Laser for Your Business, What to Choose

- Common use problems of punching and laser cutting parallel machine What are the common use problems of punch-laser parallel machine

- What Are The Benefits Of Using Laser Cutting As Opposed To Flashing