When it comes to the world of manufacturing, change is good. Companies, such as Zhongqi, are always searching for innovative methods to improve their products. A few of the more exciting changes now occurring involves how drill bit manufacturers are learning to adapt new materials. The materials: Specifically, they are moving toward TPU and bio based material. And these materials aren’t just better ones for making products; they are also friendlier to the environment. But when we consider how these innovations are transforming the industry, it’s clear that they can be used to make people more successful and provide better tools for all

How can the TPU/Bio-based material help Drill Bits Manufacturers achieve a better performance

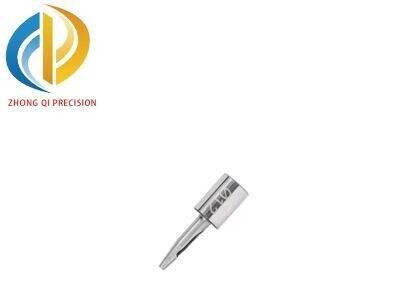

Manufacturers of drill bits are constantly looking for ways to make their products stronger and more efficient. One way they are doing that is by utilizing TPU, which stands for thermoplastic polyurethane. TPU is pliable and strong material. It can take a beating and it does not wear out. This is to say that a TPU drill bit can outlast a conventional material drill bit. This is welcome news for construction workers and building companies that depend on these tools as part of a daily routine. Bio-based products, meanwhile, are produced with raw materials from nature. This makes it a more sustainable option. Companies like Zhongqi are in the vanguard, producing drill bits that not only work well but also reduce pollution. Now, picture a drill bit that not only excels at steering into deep rock, but also provides some benefit to the planet! Incorporating these advanced materials, manufacturers can produce items for today’s work life and take care of the planet at the same time

No doubt, making these materials work in manufacturing is not always a simple or straightforward process. It will take new machines and new methods. But companies are spending on the latest technology to make this possible. For example, they may utilize special molding processes to mold TPU into the optimal drill bit configuration. That could result in drill bits with of custom shapes that help them burrow through materials more effectively. The output is a ‘better’ tool, one that saves time and effort to those who employ it

Solutions and Tips

And for companies that do want to use TPU and bio-based materials, there are various key points to consider. First, let’s get a feel for the unique qualities of these materials. TPU isn't TPU, and picking the right type can make a big difference. Manufacturers should also take into account the processing of these materials. For instance, production may require special settings and temperatures

Another critical area to look after is training. Workers must be trained on how to handle these new materials properly. And this is going to ensure that the products we produce are excellent. Companies such as Zhongqi often offer workshops and hands-on training to update their teams on the newest technologies, materials and production methods. Working with professionals has the added plus of generating better ideas and solutions

Finally, it’s important to pay attention to market trends. Increasing customer awareness is known about sustainability and eco-friendly. So the manufacturers who can respond to these needs most effectively are likely going to win. They should sell the benefits of TPU and bio-based materials to their clients. Ultimately, the road to new materials can be a tough one — difficult to navigate and expensive to travel — but when we know what we’re doing and we work well together, manufacturers can produce spectacular tools that are good for both workers and the planet

The way drill manufacturers are responding to the needs of eco-friendly material processing

Over the years, many have become more eco-conscious. This requires companies to figure out how they can help save our planet. Now drill bit manufacturers such as Zhongqi are responding to this shift by creating products that are better for the earth. One major trend is the use of TPU, which stands for thermoplastic polyurethane. TPU plastic can be produced in a way that is less harmful to the environment. It is durable, flexible and recyclable. Making drill bits Drill bit is great to be used as a drill bit

Eco-friendly materials are in the works at Zhongqi for their drill bits. We know the interest in processing and use of these materials. When producing drill bits from TPU or bio-based materials, the manufacturers need to adapt the way that they design and manufacture these tools. For instance, the systems used for drilling drill bits may need modification to accommodate TPU successfully. That means that manufacturers have to make new investments in technology and their workers. In this way, they are able to design drill bits that are not only good for the earth but also very efficient for various tasks

A critical piece of applying eco-friendly materials is ensuring that the drill bits function just as they should with traditional ones. Zhongqi tests their drill bits to high level of performance. This way, customers can have confidence that the product is actually good for the environment and does what it says. Manufacturers are inventing new techniques to do more with less. This requires both less energy and less waste, which is better for the planet. In the end, drill bit makers such as Zhongqi are more than meeting the challenge to contribute in these environmentally-protective oreo-friendly effort

Where is the best place to wholesale high quality TPU/Bio-Based drill bits

There are number of locations to purchase high quality TPU or bio based drill bits for sale. Prices and quantities at wholesale sources are frequently better for companies, which also makes sourcing what they need less of a barrier. Zhongqi is one of the best sources of these earth-friendly drill bits. They have such a variety of great items and they are all created with the utmost care for quality

There are a few important things that you should think about when searching for some good wholesale suppliers. First of all see to it that the supplier is widely accepted. What this means is they do indeed have satisfied customers and products that people want. Zhongqi is committed to the quality of its drill bits and their eco-friendly, reliability. Also consider there is a selection of products. A decent supplier will have different sizes and types of drill bits for you to select from. That way, customers can locate the perfect tools for their projects

It’s also useful to seek out suppliers that disclose what they use and how products are produced. This openness suggests that the company cares about quality and the environment. Zhongqi explains how they manufacture their drill bits and what materials they use. This guidance enables customers to make well-informed decisions and feel good about their purchases. Also take into account the customer service element of the supplier. With such a customer friendly and responsive team can make all the difference when it comes time to place an order or ask questions

It is also a good idea to find wholesale sources that are willing to give you a discount when you buy in bulk. This can save money and make it easier for businesses to stock up on environmentally friendly drill bits. For buyers who purchase in volume, Zhongqi frequently offers special deals that can make this the smart choice for businesses eager to go green on a dental budget. By selecting such a name as your wholesale source, you are able to get high quality drill bits and simultaneously support green practices

What Are The Current Trends In Drill Bit Technologies Developed For TPU/Bio-Based Materials

The field of drill bit manufacturing is a changing one and more firms are now paying attention to eco-friendly materials in TPU and bio-based products. One of the newest trends is research and development. Advertisement Companies like Zhongqi are dedicating themselves to thinking up new ways to make drill bits stronger and more efficient while using less environmentally harmful materials. That’s why engineers and designers are collaborating as never before, designing products that thrill customers at the moment of purchase, when they open the box, and using them for years – all while using less resources

And then there's the growing role of technology in production. Many manufacturers are moving to cutting-edge machines that can more easily process new materials such as TPU. This technology raises the accuracy of drill bits and simplifies making them in large batches. Zhongqi is leading the trend and now they are using advanced machines to produce high quality drill bits that works well and environmental friendly together. This is not only good for the environment, but means that customers have equipment they can depend on

Drill bit manufacturing is also increasingly influenced by sustainability. Other companies are increasingly studying how to cut down waste and reduce their carbon footprints. This includes ways to recycle materials and made of renewable resources in their products. Zhongqi is an environmentally friendly studio and they are looking for ways to make their production process greener. It could mean employing energy-saving equipment or partnering with suppliers with sustainable approaches

Finally, there is an increase in cooperation between manufacturers and customers. Companies are paying attention to what customers want in drill bits, and need. This is the only way they can develop products that are not only good for the environment, but ludicrously handy for their customers as well. We at Zhongqi are a customer centric company and your feedback is used to further improve our product. Remaining cognizant of these trends will allow drill bit manufacturers to keep up with current demand for green materials and high-performing tools

Table of Contents

- How can the TPU/Bio-based material help Drill Bits Manufacturers achieve a better performance

- Solutions and Tips

- The way drill manufacturers are responding to the needs of eco-friendly material processing

- Where is the best place to wholesale high quality TPU/Bio-Based drill bits

- What Are The Current Trends In Drill Bit Technologies Developed For TPU/Bio-Based Materials